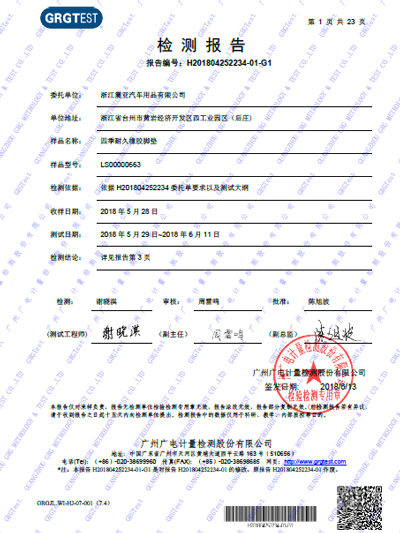

1. Quality system

3W strictly controls product quality according to the requirements of the 16949 standard, and succeeded in the certification of IATF16949:2016 in January 2018;

2. Test ability

The company has a laboratory to monitor the performance of raw materials and products in the warehouse;

In order to ensure that the odor of the company's automotive interior parts meets internal control and customer requirements, an odor evaluation room is set up and an odor evaluation team consist of 7 third-party personnel with certifications is formed to evaluate the odor of the company's raw materials and finished products;

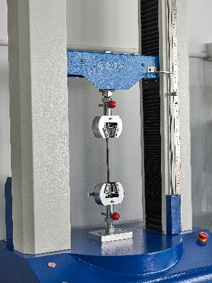

| NO. | equipment name |

picture |

test items |

| 1 | Universal material testing machine |  |

Mechanical properties such as stretching, peeling, bending, and compression of non-metallic materials |

| 2 | Melt mass flow rate meter |  |

Melt mass flow rate meter |

| 3 | hardness tester |  |

Hardness of vulcanized rubber and plastic products |

| 4 | Density balance |  |

Density of solids, liquids, granules, powders, etc. |

| Serial number | project | Serial number | project |

| 1 | exterior | 12 | Odor performance test |

| 2 | Pilling | 13 | Normal temperature peel strength test, N/mm |

| 3 | High temperature resistance | 14 | Peeling force after environmental cycle, N/mm |

| 4 | Low temperature resistance | 15 | Atomization, mg |

| 5 | Hot and cold alternating performance | 16 | Light aging resistance |

| 6 | Color fastness to wear, grade | 17 | Floor mats buckle insertion force, N |

| 7 | Color fastness to water, grade | 18 | Floor mats buckle endurance test |

| 8 | Tear strength (horizontal/longitudinal), N | 19 | Banned and restricted substances |

| 9 | Heat shrinkage rate, % | 20 | Volatile limit standard |

| 10 | Slip resistance | 21 | Anti-mildew ability |

| 11 | Combustion test, mm/min |